How to Minimize Buckling of Asphalt Shingles

Plywood and OSB roof sheathing are the most popular roof sheathing materials in the U.S. for a good reason: they are easy to work with, readily available, and perform the job well. But they must be installed correctly. Improper installation of roof sheathing panels can result in warping, or buckling, of asphalt shingles. Ensure optimum performance of finished roofing by following these recommendations.

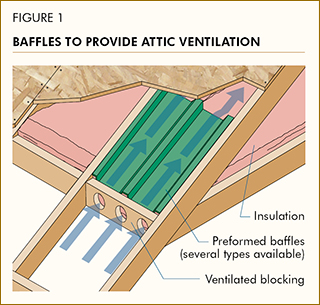

Provide roof ventilation according to building codes

(see hints below and Figure 1).

Ventilation hints:

- Provide a minimum net free ventilation area of 960 square inches for each 1,000 square feet (1/150th) of ceiling area is required. Net free ventilation area may be reduced to a minimum of 480 square inches for each 1,000 square feet (1/300th) when certain building code provisions are met.(a) Note that these provide the minimum ventilation code requirements, which has been found to be adequate under most normal circumstances.

- Vent exhaust air from kitchens, baths, and laundry to outdoors with vent pipes that run through the roof cavity or attic to roof ventilators. Do not vent exhaust air directly into roof cavity or attic.

- Install baffles providing a minimum of 1 inch of clear space between framing and/or under roof sheathing at eaves to insure that ceiling or roof insulation does not block ventilation paths. For vaulted or cathedral roof construction, provide free ventilation path from eaves to ridge between all rafters.

Install a Vapor Retarder. In cold climates, a vapor retarder on the warm side of the ceiling minimizes the amount of water vapor entering the attic and reduces the ventilation requirements as noted above. Openings in the ceiling created for electrical fixtures and plumbing stacks should be sealed so there is no air leakage between the living area and the attic space. A vapor retarder should also be used on the ground in crawl-space houses.

Store Panels on Stringers or Supports. Acclimate panels prior to installation whenever possible and protect sheathing against direct exposure to inclement weather. Store panel bundles on level 4x4 stringers or other supports, so they are not in direct contact with the ground. At least three stringers should be used to support 8-foot panels–one centered and the other two approximately 12 to 16 inches from the ends. Cut banding on panel bundles to prevent edge damage. If plastic sheets or tarps are used, keep them open at the bottom and provide ample space on top and all sides to ensure good air circulation around the panels. Even though the weather will not affect the structural integrity of APA Rated Sheathing, it should be covered when stored outside to keep it clean and to prevent uneven accumulation of moisture. See Storage and Handling of APA Trademarked Panels, Form U450, for more storing and handling tips.

Space Panels 1/8 Inch. Due to the manufacturing process, sheathing may be very low in moisture content when produced. Because panels will increase in length and width as they absorb moisture from humid air or from rain, it is recommended that panels be spaced 1/8 inch at ends and sides when fastened to framing.

Fasten panels to framing with 8d common nails (0.131 x 2-1/2 inches). Space nails 6 inches o.c. along panel ends and supported edges, 12 inches o.c. along intermediate framing.(b) Place fasteners 3/8-inch from panel edges. Staples may be used in accordance with code approvals for size and spacing. To further minimize unevenness in the sheathing, align framing properly and block any warped framing to ensure panels are smooth and flush at joints. See Prevent Buckling with Proper Spacing, Form M300, for more information on proper spacing.

Stand Over Rafters or Truss Chords When Installing Panels. Standing between supports may bend a panel. Fastening it while bent can "lock" the bent shape into the panel. Although the roof is not harmed structurally, these depressions between the supports can result in an unacceptable appearance.

Store Shingles according to manufacturer's recommendations.

Install Shingle Underlayment Over Dry Sheathing. Install the underlayment felt as soon as practical to avoid direct rain on the panels. Allow panels that get wet to dry before applying felt. Install the felt smoothly, and remove any wrinkles that develop prior to application of the shingles. If the felt is wrinkled, the shingles may not lie flat, causing appearance issues.

Underlayment should conform to ASTM D226 Type I, ASTM D4869 Type I or ASTM D6757. Self-adhering polymer modified bitumen sheet underlayment should conform to ASTM D1970. See Proper Installation of APA Rated Sheathing for Roof Applications, Form N335, for more information on installation.

Postpone application of shingles as long as practical to allow roof sheathing time to acclimate.(c) Sustained high humidity will allow dry panels to equilibrate more rapidly than lower humidity. In order to ensure proper performance of the roof assembly, it is important that asphalt shingles be installed in accordance with the shingle manufacturer's installation recommendations.

Considerations for Asphalt Shingles. Shingles vary considerably in their weight, surface texture and composition. The IBC and IRC require that asphalt shingles meet ASTM D225 or ASTM D3462 standards. Minor surface imperfections in the substrate are more likely to affect the appearance of thin, lightweight, untextured shingles. Consider darker, heavier-weight shingles, including those that are laminated, textured, or varicolored, in order to mask surface imperfections.

Suggestions for repair of roof shingle buckling are provided by shingle manufacturers or the Asphalt Roofing Manufacturers Association.

(a) See Section R806.2 of the 2015 International Residential Code or Section 1203.2 of the 2015 International Building Code for more details.

(b) 6 inches when spans are 48 inches or greater. Check building code for proper nail size and spacing requirements in high-wind areas.

(c) Refer to shingle manufacturer's recommendations.

We have field representatives in many major U.S. cities and in Canada who can help answer questions involving APA trademarked products. For additional assistance in specifying engineered wood products, contact us:

APA HEADQUARTERS: 7011 South 19th Street, Tacoma, Washington 98466 • (253) 565-6600 • Fax: (253) 565-7265

APA PRODUCT SUPPORT HELP DESK: (253) 620-7400 • E-mail: help@apawood.org

Disclaimer: The information contained herein is based on APA – The Engineered Wood Association's continuing programs of laboratory testing, product research, and comprehensive field experience. Neither APA, nor its members make any warranty, expressed or implied, or assume any legal liability or responsibility for the use, application of, and/or reference to opinions, findings, conclusions, or recommendations included in this publication. Consult your local jurisdiction or design professional to assure compliance with code, construction and performance requirements. Because APA has no control over quality of workmanship or the conditions under which engineered wood products are used, it cannot accept responsibility for product performance or designs as actually constructed.

Form No. K310R/May 2015

© 2015 APA – The Engineered Wood Association. All Rights Reserved.