Looking for beautiful, cost-effective replacements for expensive, hard-to-source large timbers in historical retrofit projects? Look to structural engineered wood products, manufactured in a wide variety of sizes and finishes that fit seamlessly into any large-scale remodel.

Appleton Mills, Lowell, Massachusetts

Appleton Mills, Lowell, Massachusetts

The Appleton Mills complex, located in a historically significant urban National Park, includes 5 million square feet of space. The original structure was built in the 1870s with a second building added in 1906. The original building relied primarily on 12- to 15-inch-thick southern yellow pine (SYP) heavy timbers, spaced 9 feet on center, and 3-inch thick SYP decking.

At the time the project began, with a goal of creating live/work lofts for artists, the buildings had been abandoned for about 20 years and were leaking in areas where the roof was missing. Nearly 40% of the floors had collapsed from rot. The timbers couldn’t be saved—two decades of exposure had deteriorated them beyond repair—and the developers were required to replace them with wood to meet historical regulations. As a result, the structures had to be completely gutted, including the framing, down to just the existing 3-foot-thick brick walls.

The design team turned to glulam, which the National Park Service determined was a suitable replacement for the heavy timbers that can no longer be found. APA member Rosboro provided 2-1/4-inch-by-21-1/2-inch glulam for the floor deck. “The glulam planks were integral to building the structure on schedule and safely,” says Matt Bagedonow, vice president of CWC Builders, noting that the glulam allowed the team to maintain temporary steel bracing for the existing walls and remove it as the new floors were added, incrementally increasing the lateral stability of the walls until they were fully braced by the new floors. In addition, installers used the glulam planks to create a platform to work as they built upward. “Also, structurally, we have to provide a diaphragm action for the floor; we were able to prove we could do that with the planks by screwing them together. Glulam was really key to getting this project done. It was indispensable.”

The design team turned to glulam, which the National Park Service determined was a suitable replacement for the heavy timbers that can no longer be found. APA member Rosboro provided 2-1/4-inch-by-21-1/2-inch glulam for the floor deck. “The glulam planks were integral to building the structure on schedule and safely,” says Matt Bagedonow, vice president of CWC Builders, noting that the glulam allowed the team to maintain temporary steel bracing for the existing walls and remove it as the new floors were added, incrementally increasing the lateral stability of the walls until they were fully braced by the new floors. In addition, installers used the glulam planks to create a platform to work as they built upward. “Also, structurally, we have to provide a diaphragm action for the floor; we were able to prove we could do that with the planks by screwing them together. Glulam was really key to getting this project done. It was indispensable.”

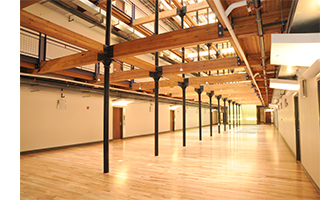

Along with the floor system, the builders used glulam for all of the girders and floor beams, as well as to replace 8x8 heavy timber columns in the older building. “The glulam allowed us to replace the heavy timbers while still meeting historical requirements,” says Bagedonow. The industrial-grade beams were stained and left exposed in the 12- to 13-foot ceilings; in some of the 125 units, the floor decking above is also visible. “They look terrific,” adds Bagenow. In the second building, CWC was able to salvage, sandblast and reuse the existing cast iron columns.

Similar historical provisions had to be met with walls and fenestration, including new aluminum windows that replicate the look of the originals. For unsalvageable portions of the façade, CWC located a brickyard south of Boston that uses the same clay as the original brick, allowing the team to replicate the look and color to maintain a seamless look throughout the exterior. While the historical nature of the building’s appearance is maintained, modern amenities abound inside, including an efficient heat pump system, modern appliances and kitchens, sound-abatement strategies and a green roof.

For more information, download Case Study: Appleton Mills, Form R145. GET >

Audrain Museum, Newport, Rhode Island

Audrain Museum, Newport, Rhode Island

The unique building was designed by New York architect Bruce Price in the early 1900s and features intricate exterior detailing. Its transformation from a worn-around-the-edges modified office building into a car museum and upscale workspace blends vintage charm and high-end appeal. On the high-ceilinged first floor, golden-era automobiles and muscle cars glisten through full-height windows. Above, new offices make better use of the space with a high-end vibe well-suited to their location.

But getting to that point required some heavy lifting from a new, more robust building frame. The car museum houses a range of vintage autos, including a WWII-era vehicle weighing in at one-and-a-half tons. Engineer Mike Camera of Camera/O’Neill Consulting Engineers knew that the original 2x12 flooring system needed to be removed and replaced to accommodate the additional weight. The team at Parker Construction kept the outer shell and the original brick bearing walls, which divide the basement into six sections. On the ground floor, the structure was framed with steel columns and 20-foot, 3-1/2-inch-by-9-1/2-inch glulam beams from APA member Anthony Forest Products, spaced 12 inches on center, spanning each bay. The glulam not only accommodated the span requirements for the frame, but also was more readily available than some of the other framing alternatives the design team considered.

Though the beams will be largely unseen in the low basement storage area and were coated with fire retardant, “The glulam was milled so well, we could have left them exposed,” says David Louttit, project manager at Parker Construction. Structural-rated Douglas fir 2x6 timbers run perpendicular to the glulam beams, with 3/4-inch tongue-and-groove CDX plywood in between. For the second-floor frame, exposed steel trusses provide an industrial look.

Though the beams will be largely unseen in the low basement storage area and were coated with fire retardant, “The glulam was milled so well, we could have left them exposed,” says David Louttit, project manager at Parker Construction. Structural-rated Douglas fir 2x6 timbers run perpendicular to the glulam beams, with 3/4-inch tongue-and-groove CDX plywood in between. For the second-floor frame, exposed steel trusses provide an industrial look.

Along with the challenges of preserving the look and beefing up the structural frame, the construction team faced severe time constraints: a schedule with less than half the normal turnaround time. To meet the deadline, Louttit had crews on site 16 hours a day, seven days a week; they also shrink-wrapped the structure to eliminate impacts from weather.

While the project sports a new structural wood frame, the team took great care to preserve as many of the original decorative elements as possible, including ornamental metal and millwork. The front façade features the original brick, intricate terracotta around the windows and similarly ornate roof cornices. The arch-top windows reach from the first floor through to the office space upstairs. A new set of bi-fold doors, fabricated to reflect the original windows, provides access for the display vehicles.

For more information, download Case Study: Audrain Museum, Form Q125. GET >